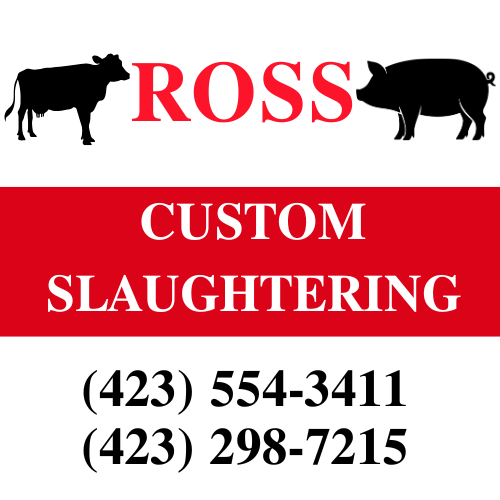

Gallery — Inside Ross’s Custom Slaughter

A Look Inside Our Local Butcher Shop

Our Gallery gives you a behind-the-scenes look at Ross’s Custom Slaughter, a trusted, family-run custom slaughterhouse in Graysville, Tennessee. We believe in transparency, cleanliness, and craftsmanship — and we’re proud to show how our work is done.

Every photo featured here represents a part of our day-to-day process: from receiving animals and preparing cuts to packaging finished meat for pickup. Our facility reflects the same values that define our business — honesty, precision, and pride in doing the job right.

While each photo captures a small part of the story, our goal is always the same: to provide safe, custom-cut meat for families and farmers across Rhea County and surrounding communities.

Our Facility and Equipment

Cold Storage and Temperature Control

Temperature control is essential to maintaining freshness. You’ll see images of our

cold storage areas, where processed meat remains properly chilled until pickup. This consistent environment prevents spoilage, locks in flavor, and ensures safe handling from start to finish.

Clean, Organized, and Well-Maintained

Our processing facility is kept spotless, with equipment sanitized daily and surfaces cleaned between every job. We operate with strict attention to detail to maintain food safety and quality. The gallery highlights:

- Our modern cutting tables and stainless-steel surfaces

- Refrigerated storage areas for hanging and cooling meat

- Clean workstations for deboning and trimming

- Organized packaging and labeling areas

Each piece of equipment plays a role in ensuring that the meat you bring us is handled safely and processed efficiently. Clean facilities aren’t just about appearance — they’re part of our promise of professional meat handling every single day.

Our Team at Work

Skilled, Experienced Butchers

Our gallery includes moments from the cutting floor — skilled butchers trimming, slicing, and packaging with care. Each team member brings years of experience and dedication to the craft of custom meat processing.

We take pride in working by hand. Every steak, roast, and grind is cut according to your specific preferences. Our team members check, label, and double-check each order to ensure accuracy and satisfaction.

A Family-Owned Tradition

You’ll also find photos showing the family nature of our business. Ross’s Custom Slaughter isn’t a corporate processor — it’s a local, hands-on operation built on tradition and trust. We’ve grown through word of mouth and repeat customers who appreciate our consistency and care.

Our gallery reflects that personal touch. Each image captures real work being done by people who live and farm right here in Rhea County.

From Drop-Off to Pickup

Cutting and Deboning

Inside the facility, you’ll see butchers using sharpened tools and steady hands to perform precision cutting and deboning. Each step is done manually to ensure the highest yield and quality. Trimming excess fat, portioning steaks, and preparing roasts all require skill and patience — and our gallery shows that process up close.

The Drop-Off Process

Several photos show the outdoor receiving area, where customers bring animals for processing. Whether it’s a beef cow, pig, sheep, goat, or deer, our team carefully tags, logs, and stores each animal immediately. Every order remains separated and documented for complete traceability.

Packaging and Labeling

Finished cuts move to our packaging area, where each piece of meat is wrapped, labeled, and sealed. The photos highlight organized freezers and clearly marked boxes, ready for customer pickup.

Labeling includes the cut name, so customers can easily identify what’s in each package.

Retail Meat and Products

In addition to custom processing, our gallery showcases the retail side of our business — displays of fresh beef and pork cuts available for walk-in purchase. These photos illustrate how we prepare and present our meat for customers who prefer to buy locally raised products.

You’ll see examples of packaged steaks, ground beef, roasts, ribs, and sausage, all arranged for easy selection. The images reflect our farm-to-table approach, showing that we control every step — from raising the animals to preparing the final product.

Serving the Local Community

Our gallery also includes photos taken around Graysville and nearby farms, showing our connection to the local agricultural community. Many of our customers are neighbors, farmers, or hunters who rely on us season after season.

We’re proud to serve them, and the images remind us why we do what we do — to provide safe, affordable, and high-quality meat for families in our region.

Commitment You Can See

When you view our gallery, you’re seeing more than a business. You’re seeing the care and dedication that go into every cut. From the clean floors to the labeled packages, every detail is intentional. It’s proof that

Ross’s Custom Slaughter is more than just a butcher — it’s a trusted part of the Graysville community.

Contact Ross’s Custom Slaughter

To schedule your next drop-off or ask questions about processing requirements, please contact us directly:

Contact Us

We will get back to you as soon as possible.

Please try again later.